Vestel is sensitive about the application of Occupational Health and Safety (OHS) policies and practices in order to provide a safe and healthy working environment, and it attaches importance to the assessment and management of the potential impacts of all risks that may result in loss, injury or damage due to any danger in the workplace to employees, contractors, supply industries, visitors, solution partners and other employees in working areas. Its goals include risk and hazard assessments to identify what could cause harm in the workplace, raising employee awareness, improving and developing processes, creating ergonomic work areas, ensuring that the most stringent safety measures are taken regarding change of operations, providing a safe and healthy working environment to employees, preventing occupational diseases and achieving zero accidents. Vestel’s Occupational Health and Safety Policy is available as below:

- All levels are responsible for occupational health and safety. We will create a safe workplace environment by eliminating the hazardous and unhealthy conditions that may arise during our activities at Vestel, by placing emphasis on the assessment and management of the potential impacts of workplace risks on employees, subcontractors, sub-industry companies, visitors and our solution partners.

- We will continuously improve our OHS performance by using the best available technologies. We will follow up the effectiv eness of the trainings by providing resources and opportunities for OHS trainings that may be required.

- By adopting the “job fit to employee and employee fit to job” principle, we will conduct risk analysis of unsafe situations and unsafe acts in the workplace in order to prev ent or reduce injuries, occupational accidents and occupational diseases. We will eliminate or minimize these risks by preparing and implementing preventive plans. By rev iewing the w orking conditions frequently, we will apply for measures in the failing fields, and we will provide resources for these measures.

Occupational Health and Safety trainings are provided within the scope of national legislation requirements. With the aim of increasing facility safety along with national legislation, job-specific trainings covering international standards are also given periodically, both practically and theoretically. The suitability of the Vocational Qualification Trainings (VQA) which are job-specific is continuously monitored and audited. All these trainings are provided to employees which are working at Vestel Manisa facilities, visitors, subcontractors, etc. includes all persons.

OHS PERFORMANCE INDICATORS1

| Employees |

2018 |

2019 |

2020 |

2021 |

| Number of Fatalities |

0 |

0 |

0 |

0 |

| Lost-Time Injury Frequency Rate2 |

25.32 |

26.17 |

18.90 |

24.36 |

| Lost-Time Injury Severity Rate3 |

|

0.21 |

0.15 |

0.21 |

| Occupational Disease |

0 |

0 |

0 |

0 |

| Contractor Employees |

2019 |

2020 |

2021 |

| Number of Fatalities |

0 |

0 |

0 |

| Lost-Time Injury Frequency Rate2 |

18.21 |

26.85 |

39.84 |

| Lost-Time Injury Severity Rate3 |

0.05 |

0.08 |

0.18 |

| Occupational Disease |

0 |

0 |

0 |

1These indicators represent the consolidated data of Vestel Elektronik, Vestel Beyaz Eşya, Vestel Komünikasyon and Vestel Ticaret companies.

2Lost-Time Injury Frequency Rate = Total Number of Occupational Lost Time Accidents x 1,000,000 / (Total Working Days - Non-Working Days) x Daily Working Duration

3Lost-Time Injury Severity Rate = Total Number of Lost Days x 100 / (Total Working Days vs. Non-Working Days)

All managers at all levels are responsible for OHS risks and issues. The Safety and Administrative Affairs Director oversees

the implementation of OHS issues and OHS targets are included in the performance evaluation of the Safety and Administrative Affairs Department. OHS issues are handled at the OHS Board, which convenes regularly (at most every two months) or immediately after emergencies, under the management of the Representative of the Employer, who represents the Company’s Senior Management. Department managers of plants assigned by the Employer or the Representative of the Employer, OHS experts, workplace physicians, human resources experts, administrative affairs experts and employee representatives attend OHS Board meetings as per the Regulation on Occupational Health and Safety Boards. Occupational

accidents, near misses, employee notifications, and identified occupational safety risks are shared with all participants during OHS Board meetings, and any resolutions issued during the meeting are announced to all managers, including the General Manager. Action processes are systematically implemented and monitored via the Occupational Health and Safety Management System (ISIGYS) software, which Vestel designed and was accepted within the integration work of the Ministry of Labor and Social Security of the Republic of Turkey.

In case of occupational accidents, Vestel analyzes the incident by conducting an accident site investigation and root cause analysis with the employee who had the accident, the relevant department manager, the OHS expert, the workplace physician and the employee representative. The Company draws up an occupational accident report by recording details and images of the accident and then take action with officials of the relevant department in order to prevent such accidents from recurring and to eliminate future potential risks. Its employee representatives play an important role in the increase in participation in activities related to occupational health and safety in their plants and in follow-ups of these activities. Vestel has a total of 287 employees representatives, who are selected by election, from each department. Ensuring the identification of sources of danger and risks, demanding necessary measures to be taken, representing employees at relevant meetings, taking part in risk analyses and occupational health and safety activities are among the duties of chief employee representatives.

Vestel enables its employees to report unsafe situations and behaviors they encounter, potential accident risks, suggestions and requests by filling out an online form. These notifications are first forwarded to the OHS expert through the occupational health and safety portal. Then, an on-site evaluation is performed with the employee filing the notification, an official of the relevant department, the OHS expert and the workplace physician to create a report and necessary actions are taken by the officials of the relevant department.

Vestel provides personal protective equipment to all its employees within plant areas, specific to their work and fulfilling certain standards. It also conducts regular inspections to ensure the safety of equipment. Occupational hygiene and indoor

environmental quality measurements (incl. noise) are regularly made by accredited organizations every year and it takes necessary measures in cases of non-compliance. Vestel conducts periodic health check ups for all its employees. It

approves the entry of chemical substances into the plant by performing technical and preliminary evaluations and through

consultations with the OHS expert, workplace physician and officials of the relevant department. It allows the use of chemicals after the completion of field trials and employee trainings.

In addition to its employees, Vestel develops various training programs covering occupational health and safety issues in order to raise the knowledge and awareness of contractors about OHS to the highest levels. In this context, the training hours given to Vestel employees and contractors are summarized in the table:

| OHS TRAININGS |

2019 |

2020 |

2021 |

| OHS Training Hours for Employees |

117.753 |

139.994 |

137.496 |

| OHS Training Hours for Contractor

Employees

|

2.778 |

5.154 |

4.457 |

Vestel continued to organize OHS trainings for all employees in line with social distancing rules, legally-regulated

capacities, limited attendance and ensured that the training rooms were disinfected before and after each training throughout the COVID-19 period.

Occupational Health and Safety trainings are provided within the scope of national legislation requirements. With the aim of increasing facility safety along with national legislation, job-specific trainings covering international standards are also given periodically, both practically and theoretically. The suitability of the Vocational Qualification Trainings (VQA) which are job-specific is continuously monitored and audited. Defined trainings are given in the table below.

| OHS Training Subjects |

| Duties And Responsibilities Of Emergency And Crisis Management Members |

| Matters To Be Considered During The Earthquake |

| Pregnant And Nursing Employees |

| Ohs Board Members |

| Legal Consequences Arising From Work Accidents And Occupational Illness |

| Functioning And Duties And Responsibilities Of The Emergency Organization |

| Emergency And Fire Fighting |

| Emergency And Fire Fighting (Refreshing) |

| Occupational Safety In Works To Be Done During Maintenance Stop |

| Safe Operation In Maintenance And Repair Works |

| Safe Operation With Compressed Gas Cylinders |

| Biological And Psychosocial Risk Factors |

| Duties And Responsibilities Of The Employee Representative |

| Work Specific Risks |

| Fire Prevention And Fire Fighting In The Working Area |

| Safe Operation With Displayed Tools |

| Safe Operation With Hand Tools |

| Safe Operation In Electrical Works |

| Safe Operation In Manual Lifting And Handling Works |

| Ergonomic Factors |

| Labeling Locking (Eked) Systems |

| Physical Risk Factors |

| Safe Operation With Forklift |

| Job Replacement |

| Safety And Health Signs |

| Application Of Disease Protection Principles And Techniques |

| Safe Operation In Construction Works |

| Safe Operation With Dock |

| Safe Use Of Work Equipment |

| Causes Of Occupational Accidents And Protection Principles |

| On Work After Work Accident |

| Occupational Health And Safety (By Job) |

| Occupational Health And Safety (Refreshing) |

| Occupational Health And Safety General Rules And Safety Culture |

| Duties And Responsibilities Of The Pointer (Maneuver) |

| Safe Working On Lifting Vehicles |

| Safe Work In Closed Areas |

| Safe Work With Chemical Materials |

| Use Of Ppe (Personal Protective Equipment) |

| Root Cause Analysis Application Method |

| Machinery Safety And Safety |

| Risks And Safety Measures On Machines |

| Description And Safe Use Of Manlift |

| Causes Of Occupational Disease And Principles Of Protection |

| Online Work Safety (Refreshing) |

| Explosion And Explosion Protection Safety |

| Analysis Of Local Events And Matters To Be Considered |

| Risk Analysis Application Method |

| Risk Assessment Team Duties And Responsibilities |

| Damages And Passive Influence Of Tobacco Products |

| Safe Use Of Lifelines |

| Safe Working Techniques At Height |

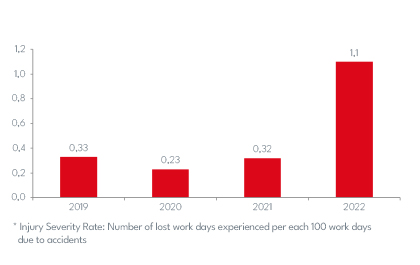

Vestel Elektronik Sanayi ve Ticaret AŞ – Injury Severity Rate*

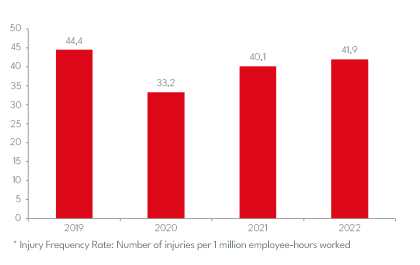

Vestel Elektronik Sanayi ve Ticaret AŞ – Injury Frequency Rate*

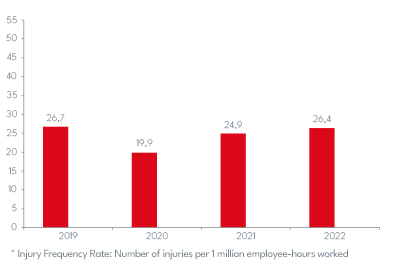

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ - Injury Severity Rate*

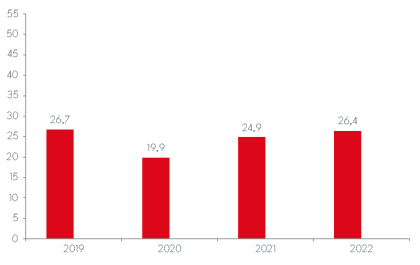

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Injury Frequency Rate*