ENVIRONMENTAL MANAGEMENT SYSTEM

Vestel Elektronik Sanayi ve Ticaret AŞ (“Vestel Group of Companies”, “Vestel”) continues its activities with nearly 20,000 employees on a consolidated basis, within Zorlu Holding AŞ, which it joined in 1994. Vestel Group of Companies has three production companies:

- Vestel Elektronik (“Vestel Elektronik”, referred to as the name of both Vestel Group of Companies and electronic factories).

- Vestel Komünikasyon

- Vestel Beyaz Eşya

Vestel Elektronik has six factories (electronic card, EPS, plastic, pre-assembly, High-End, digital factory) which are located in Manisa Organized Industrial Zone. It received ISO 14001 Environmental Management System in 1998, ISO 50001 Energy Management System in 2012 and ISO 14064 Greenhouse Gas Verification Statement in 2017.

Vestel Komünikasyon manufactures electric vehicle chargers, set-top boxes, LED lighting and batteries and is located in the Aegean Free Zone. The Company received ISO 14001 Environment Management System in 2020 and ISO 14064 Greenhouse Gas Verification statement Certificates in 2022.

Vestel Beyaz Eşya Sanayi ve Tic. A.Ş. (“Vestel Beyaz Eşya”), continues its activities in Vestel City, which is located in the 3rd Section of the Manisa Organized Industrial Zone with nearly 10.000 employees. Vestel Beyaz Eşya has TS EN ISO 14001 Environmental Management System Certificates since 2010 and TS EN ISO 50001 Energy Management System Certificates since 2012, and in its seven factories (Refrigerator I-II Factories, Washing Machine Factory, Tumble Dryer Factory, Dishwasher Factory, Cooking Appliances Factory, Air Conditioning Factory and Thermosiphon Factory) implement management systems in an integrated manner. Vestel Beyaz Eşya has been calculating its carbon footprint and water footprint in accordance with ISO 14064 and ISO 14046 standards since 2016 and it has verified by accredited third party varification institutions since 2018.

Vestel Group of Companies (“Vestel”) oversees the health and safety of employees, customers and the surrounding community affected by its activities, products and services. Vestel aims to implement and develop lean and proactive Environmental Management Systems in its product, production and service activities, within the framework of the principle of sustainable development, by taking it as its duty to protect the environment and natural life for future generations.

Vestel in this direction:

- It perceives all kinds of waste disposal as a loss of natural resources and develops methods to prevent pollution at its source. It works on waste reduction, reuse, recycling and recovery.

- Continuously improves energy performance by designing energy efficient processes, supplying products and services. It aims to save energy, water and natural resources by increasing efficiency and encouraging the use of new technology.

- Considering the environmental factor in the evaluation of new products, projects and operations, it gives priority to reducing the use of harmful substances in product design and production processes, using less polluting substances and producing reliable products.

- It continues its efforts to prevent climate change by reducing greenhouse gas emissions and to protect biodiversity and ecosystems.

- In its processes, it accepts compliance with the applicable environmental legislation and administrative regulations, all legal and other requirements to which it is bound, and international business standards as a basic requirement and fulfills this requirement.

- By training its employees, subcontractors, dealers and suppliers and using continuous improvement tools; aims to minimize energy and water consumption, waste generation, water and air emissions.

- It produces products that have less environmental impact and uses more recycled materials.

- It carries out practices aimed at getting the opinions of its stakeholders on matters related to its activities, informing them about its activities and acting together in line with common goals.

- By complying with the terms of Environmental Management Systems, it encourages participation and innovation culture among stakeholders in order to continuously improve and increase the effectiveness of management systems, and provides adequate and appropriate resources in this way.

- Performs risk and opportunity analysis and evaluations without interruption.

- Continuing its sustainability efforts uninterruptedly.

You can access Vestel's Environmental Policies here.

ENVIRONMETAL TARGETS

Vestel has set its own targets in line with Zorlu Holding's Smart Life 2030 strategy which are identified as “net zero emissions”, “zero waste” and “water recovery” . In this context, Vestel's goals are:

- Achieving net zero emissions firstly in its own operations until 2030. (direct greenhouse gas emissions (Scope-1); indirect energy sourced emissions (Scope-2)); Achieving net zero emissions across the entire value chain (direct and indirect greenhouse gas emissions (Scope 1-2-3)) until 2050;

- Eliminate landfill waste by 2030;

- Recovering 50% of the water used until 2030 and all of it by 2050.

In line with Zorlu Holding's Sustainability Strategy, Vestel Elektronik and Vestel Beyaz Eşya follow strategies aimed at “net zero emissions and circularity”. In this context, energy efficiency projects will be continued in line with the target of reducing carbon emissions by 15% until 2022, and emphasis will be placed on the use of energy efficient technologies. Within the scope of the renewed Zorlu Holding Smart Life 2030 targets, Vestel Group of Companies:

- In Scope 1-2 until 2030; Achieving net zero emissions across the entire value chain (Scope 1-2-3) by 2050;

- Reducing waste by 50% by 2030 and reaching zero waste by 2050;

- It will contribute to the goals of recovering 50% of the water used until 2030 and all of it by 2050.

- 12% reduction in energy intensity (per unit product) by 2030.

- Reducing the amount of water withdrawn per unit production by 15% by 2030.

- Resetting the amount of waste sent to landfill by 2030.

Circular Economy

The linear economy model applied today is based on “take-make- waste” processes. Ignoring the rising strains on natural resources, this model paves the way for negative consequences such as economic loss and environmental pollution. In order to prevent these phenomena and protect the continuity of production, the adoption of circular models through which products are designed to be reintroduced to the economy and which change the perspective on resources and waste, accordingly come to the fore.

Circulary Economy Solutions in Vestel

Vestel operates in a sector with intensive natural resource consumption. In the design phase, the company uses fewer parts where possible to reduce the use of raw materials. Vestel uses fewer materials to produce parts through design changes and strive to increase the use of recycled and renewable materials. It pays attention to reducing the level of reprocessing and using existing molds during the production phase. The company designs the packaging quantity to be at the most appropriate level for the product and human health, so that the maximum quantity of products fits into the container during the transportation phase. Vestel aims to extend the use phase of its products and contribute to the circular economy through activities such as after sales repair, reuse and refurbishing. In this respect, Vestel design products in a way to ensure the accessibility of all parts during repair in order to facilitate the repair of the products. Adoption of circular economy models and engaging in repair, recycling and upcycling activities play a critical role in forestalling the global waste problem, while at the same time achieving financial benefits. As a company, Vestel supports the repair and recovery of products and engages in activities on this subject.

Product Recovery and Repair

Under the Material Inspection and Recovery Project, Vestel ensure that products are repaired and the defective parts are repaired and reused. Vestel authorized service providers collect all replaced defective parts, recover repairable parts to be used as spare parts for future product repairs and sort other parts by waste classes and send them to recycling. Authorized service providers evaluate the materials and spare parts replaced due to malfunction and consider them for reuse; and repair those which are available for repair. Thus, the materials that have financial value for the Company are recovered, resulting in economic gain, and potential environmental impacts are prevented by reducing the quantity of potential electronic waste as well. We recovered 41,213 spare parts in 2022. Thanks to these efforts, we saved TL 7.5 million.

Products replaced under warranty are delivered to the Returned Products Evaluation Center (DÜDEM), those available for repair are refurbished at our Refurbishing Centers, Central Repair and Recovery Centers and Small Domestic Appliances Recovery Center (KEAÜSSÜ) and sold at Vestel Outlet stores and some dealers. In 2022, we refurbished a total of 62,984 products and returned them to the economy, and we donated 91 of the refurbished products as part of our corporate citizenship projects. Non-refurbishable products are recycled through a licensed recycling company.

Vestel complies with the 2012/19/EU waste directive on the management of waste from electrical and electronic

equipment. Informative guides on how to disassemble and recycle household appliances are prepared by i4R, of which Vestel Beyaz Eşya is a member, established in line with this directive. We share these guides to help recycling/recovery facilities.

Used Phone Refurbishing

As per the Regulation on Refurbished Products issued by the Ministry of Trade of the Republic of Turkey, Vestel Customer Services has been authorized to refurbish and sell smart phones and tablets in a certified way. Under the same regulation, the Central Repair and Recovery unit affiliated to Vestel Customer Services was granted the Refurbishing Authorization Certificate by the Ministry following the Service Competency Certificate issued by the Turkish Standards Institution (TSE). Vestel is authorized by this certificate to refurbish and sell smart phones and tablets of all brands in a certified way. It will sell all refurbished products on our website

www.yineyenicep.com launched for the sale of refurbished products. The company also aims to prevent the generation of e-waste while achieving financial gain through this practice launched as a new business model.

Domestic Recycling Project

Within the scope of the Domestic Recycling Project, which started on Earth Day on April 22, 2022, old and disused white goods and electronic goods are brought back into the economy. The recycling fee obtained from the products will be donated within the scope of cooperation with the relevant non-governmental organizations in order to support the efforts to protect the natural life. In addition, for consumers who support the project by giving their old product, seed balls will be thrown with unmanned aerial vehicles in hard-to-reach areas that need to be afforested in cooperation with Ecording.

Waste Management System

Within all our activities under the Zero Waste Management System, Vestel primarily focuses on the prevention and reduction of waste generation; and the recycling and recovery of waste.

Vestel sort the waste generated at various stages of production and store it in temporary waste storage areas. It transfers all collected waste to licensed waste companies in accordance with the Waste Control Regulation and conduct regular audits of waste companies to ensure that waste is recycled or recovered in an appropriate way. By tracking waste in all processes, Vestel reduces environmental pollution and supports recycling and recovery.

Zero Waste

Under zero waste approach, Vestel recycle or recover 91.5% of production-related waste. As per the Zero Waste Regulation, Vestel ensures that the waste from its offices is sorted in an appropriate way, and it traines its employees on waste management. In 2021, the company digitalized the environment and zero waste trainings in order to reach all its employees. As part of its work, Vestel was granted the Zero Waste Certificate in 2021. From a circular economy perspective, it produced some of its waste bins using production-based waste. Also food scraps are made use under the Zero Waste practice. In 2022, Vestel composted 1747 kg of food scraps and used it for its own green areas. The company also donated 99.4 tonnes of food scraps for stray animals.

Use of Recycled Plastics and Reduction of Plastics

Vestel is working on reducing plastic raw material consumption and plastic waste generated in production processes and offices. Under the Business World Plastics Initiative, of which it is a signatory, it has made a commitment to reduce the

use of plastics and reuse them by recycling.

By recycling production and engineering scraps and residuals generated throughout all processes under the cooperation of Production, R&D and Quality Control teams and reusing them in our products and product components at Vestel Elektronik the company aims to use a total of 1,887 tonnes of recycled plastics within the next three years: 629 tonnes by the end of 2021, 629 by the end of 2022 and 629 by the end of 2023. In addition, Vestel will improve TV product and packaging designs without compromising on quality and durability and reduce the use of plastics by 831 tonnes by the end of 2023 when compared to the base year 2020 through activities to be performed under the cooperation of our R&D and Production units.

At Vestel Beyaz Eşya, it cooperates with domestic and foreign suppliers and start-ups in order to ensure the use of recycled and alternative plastic raw materials. By recovering the scraps generated throughout production processes, it aims to use a total of 7,081 tonnes of recycled plastics in products and components, including 1,983 tonnes by the end of 2021, 2,361 by the end of 2022, and 2,737 by the end of 2023. As well, it will improve the product and packaging designs of all household appliances and reduce the use of plastics by 1,000 tonnes by the end of 2023 when compared to the base year 2020 through the activities to be performed under the cooperation of our R&D and Production units.

Vestel Beyaz Eşya exceeded its commitments for the 2021-2022 period, reducing 232 tonnes of plastic in packaging materials and 2,689 tonnes of plastic in products. It used 5 tonnes of bio-based plastic materials and 4,573 tonnes of recycled plastic. Thus, it prevented the use of 7,499 tonnes of unprocessed plastics in total.

Vestel manufactures its products with sustainable materials, focusing on the environmental impact of every material that

use in our products. Vestel manufactures heat pump tumble dryers containing bio-plastics. The company reduces the use of petroleum-based plastic raw materials by using materials produced from olive pits and sugar cane in refrigerators.

Packaging Management

Breaking new ground in Turkey, Vestel started using 100% recycled and recyclable cardboard in the packaging of all Vestel-branded household appliances manufactured for Turkey at our facilities. In addition, in 2022, studies on the use of 100% recycled and recyclable cardboard packaging in televisions of certain sizes were completed and made ready for order.

In 2022, it prevented 248,608 trees from being cut by using a total of 14,624 tonnes of recycled cardboard as the Vestel Group of Companies. The Company prefers internationally-certified paper-based resources for the sustainable consumption of such resources.

For the first time in Turkey, Vestel started using FSC (Forest Stewardship Council) certified, 100% recycled cardboard in the packaging of Vestel branded refrigerator and dishwashers in 2021. In 2022, this practice was introduced for all Vestel branded major household appliances to be sold in Turkey.

Water Stewardship

Vestel monitors water consumption within the scope and objectives of the TS EN ISO 14001 Environmental Management System and follows a policy to reduce water consumption accordingly.

At Vestel, we supply the water used in manufacturing processes from the municipal water and well water (groundwater) of the Manisa Organized Industrial Zone (Aegean Free Zone for our Vestel Komünikasyon plant Being aware of the pressure on water resources, water recovery models are implemented, the effect of which is improved. We focus on minimizing water consumption, which we consider one of the most significant risks in manufacturing processes. The focus is on minimizing water consumption, which is seen as one of the biggest risks in production processes. In order to achieve this, studies are carried out to develop and expand water saving projects and to utilize water through recycling. All processes related to water management are reported to CDP. The water footprint at all Vestel's plants is verified by independent third parties within the framework of the ISO 14046 Water Footprint Standard. Waste water is also discharged to the treatment plant of the Manisa Organized Industrial Zone (Aegean Free Zone for the Vestel Communications factory).

Vestel recycles water in its paint shops, one of its biggest water consumption points. As a result of the optimization

implemented in the refrigerator paint shop, it eliminated the rinsing process and saved 43,600 m3 of water as well as 785 MWh of energy. Thus, the company saved as much as the annual water consumption of 523 people in Turkey.

Rainwater collection projects were implemented and 1,263 m3 of rainwater was collected in 2022. The dissemination project continues.

Air Quality

According to the Industrial Air Pollution Control Regulation, air emission measurements are made at all Vestel production facilities every 2 years and all parameters (CO, NOx, SOx, VOC, Dust/PM) are below the limit values.

Biodiversity

There are no habitats for species which are of importance for scientific studies and/or are or may be endangered as well as species endemic to our country, biosphere reserves, biotopes, biogenetic reserve areas, or unique geological or geomorphological formations in the Manisa Organized Industrial Zone (MOSB) and the Aegean Free Zone (ESBAŞ), where Vestel’s production facilities are located. All production facilities were assessed in accordance with the Environmental Impact Assessment Regulation (EIA) during the establishment phase and in cases of any process change and/or capacity increase. In addition, negative environmental impacts that could have arisen from construction and operation activities were assessed. As a result of previous environmental impact assessments (EIA), it was determined that no species under protection and no endangered flora species were found within the Company’s operating areas.

Since its production facilities are established in the Organized Industrial Zone and Free Zone, its operating areas are industrial areas, and there are only industrial areas within a 2 km radius of its operating areas, thus no flora-fauna studies are carried out in these regions. As Vestel, we are committed to complying with the Environmental Law No. 2872 and the regulations issued pursuant to this law regarding potential measures.

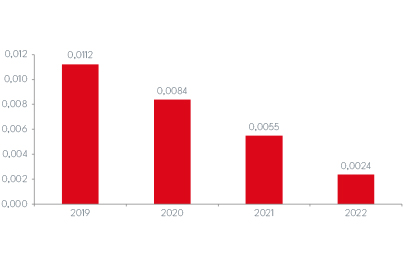

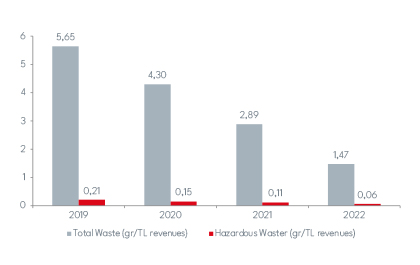

Vestel Elektronik Sanayi ve Ticaret AŞ – Waste Generation*

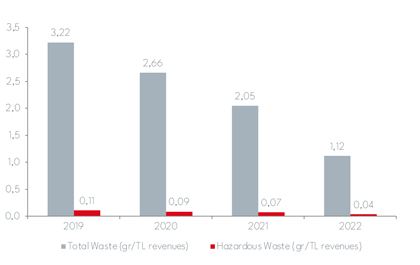

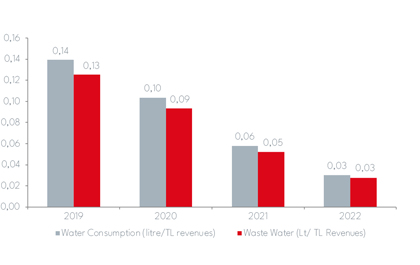

Vestel Elektronik Sanayi ve Ticaret AŞ – Water Consumption and Waste Water Generation*

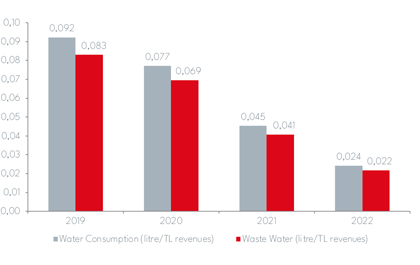

Vestel Elektronik Sanayi ve Ticaret AŞ – Total Energy Consumption (TEP/TL revenues)*

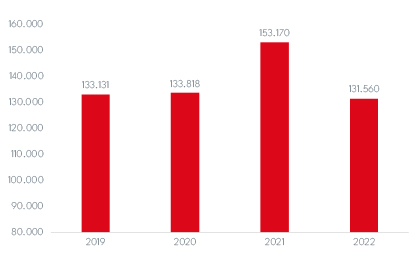

Vestel Elektronik Sanayi ve Ticaret AŞ – Total Carbon Emissions (tonnes CO2/year)*

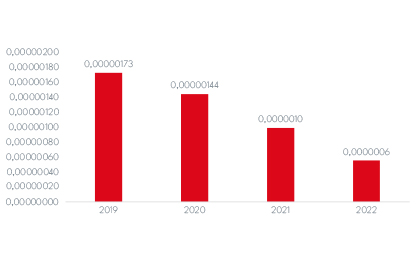

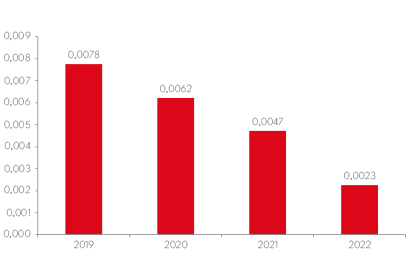

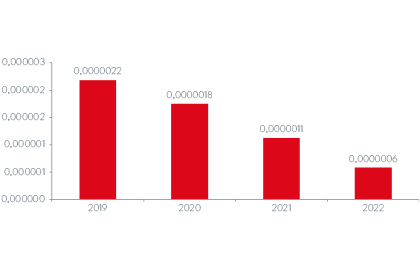

Vestel Elektronik Sanayi ve Ticaret AŞ – Total Carbon Emissions (kgCO2/TL revenues)*

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Waste Generation

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Water Consumption and Waste Water Generation

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Total Energy Consumption (TEP/TL revenues)

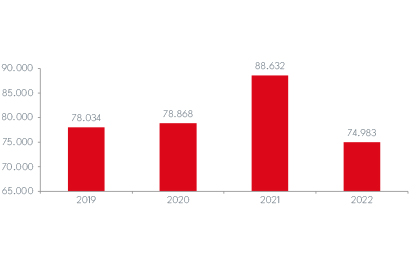

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Carbon Emissions Originating from Energy Consumption

(tonnes CO2/year)

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Total Carbon Emissions

(kg CO2/TL revenues)