Vestel believes that resource scarcity and climate crisis action should be on everyone’s agenda including both the public and private sector. The investments it made in renewable energy and energy efficiency as well as its innovative business models play a key role in the transition to a net-zero economy.

For a sustainable future, the Company needs to trigger transformation across our entire value chain. It is aware of this requirement and leverage the power of Industry 4.0 and automation to support the reduction of energy consumption through operational improvements and innovative products. Vestel implement circular models to improve resource efficiency in production and reduce its environmental impact from products.

Climate Crisis and Net Zero Targets

Vestel aims to achieve net zero emissions by 2050 and is working on its decarbonization plan as part of our commitment to set Science Based Targets (SBTi).

It is critically important to reach net zero in greenhouse gas emissions as quickly as possible to curb the climate crisis and keep global warming below 1.5 °C by 2050. To that end, the net zero targets declared by countries gain significance. The European Union aims to secure net zero emissions by 2050 through the EU Green Deal. As part of this target, it will transform its trading sectors. In addition to the EU, the USA and China, which are responsible for a considerable portion of

greenhouse gas emissions today, have committed to reach net zero emissions by 2050 and 2060, respectively. Turkey, on the other hand, ratified the Paris Agreement in 2021 and set a net zero emission target by 2053. The private sector plays a majör role in reaching these targets declared by countries. Considering the number of employees, annual production capacity and the impact of global supply chains, the potential effectiveness of private sector action is evident.

Climate Crisis Action at Vestel

To increase renewable energy generation, Vestel installed a 142 kWp solar panel at the rooftop of its utilities facility that distributes energy to refrigerator and washing machine plants in 2021. Vestel produced 175 MWh of electricity in 2022. It is aimed that renewable energy investments will continue to increase.

In line with the global agenda, Vestel aims to reach net zero emissions by 2050, first in its own operations and then throughout its entire value chain. By making low-carbon technologies more commonplace, it is on its way to becoming a climate-friendly company. In 2021, Vestel submitted a letter of commitment to set Science Based Targets (under SBTi), a major step in reaching net zero emissions. To that end, it aims to switch to technologies that cause less greenhouse gas emissions from production, increase renewable energy investments and manufacture products with high energy efficiency, less water consumption, less carbon emissions and a low environmental impact. As part of SBTi efforts, the Company started a detailed process to collect data in order to calculate Scope 3 emissions in 2021. Accordingly, it will draft a plan for both operations and the decarbonization of the value chain.

Vestel has been transparently sharing its performance with Vestel Beyaz Eşya and Vestel Elektronik reporting to the Carbon

Disclosure Project (CDP) since 2012 and 2013, respectively. In the 2022 CDP report, where 2021 was evaluated, Vestel Elektronik’s Climate Change score was B and the Water Program score was C. Vestel Beyaz Eşya’s Climate Change score was A- and the Water Program score was C. Direct and indirect emissions within the boundaries of the organization are verified by independent third parties according to the ISO 14064 standard.

Improvements in logistics operations such as increasing loweremission transport and load optimization play an important role in achieving net zero emissions in the value chain. Packaging optimization efforts help minimize space loss in container, truck and intermodal transfers for shipments from the Far East and Europe.

In 2022, Vestel Beyaz Eşya included more domestic alternative sources, enabling to downscale the total of 40,800 km. In addition, with the activation of the use of warehouses, 13.416 km of improvement was achieved by making one-time purchases from abroad instead of multiple trips. With these improvements, approximately 39.13 tons of carbon emission reduction was achieved.

In terms of after-sales services, our call center responded to and resolved 389,960 calls without technician support in 2022, preventing 1,559,840 km of vehicle movement and 611 tonnes of carbon emissions. In 2022, Vestel kicked off a pilot project for TV and freezer product groups which supports customers in installing its own products. This enabled them to transfer 9813 different service items to customers, preventing authorized service vehicle movement. In 2023, Vestel plans to have its customers deliver 25,000 services, eliminating the need for authorized service delivery.

Vestel uses environmentally-friendly refrigerants with very low global warming potential in all its refrigerators and tumble dryers. Moreover, it has reduced the quantity of refrigerant per unit product by 2.69 % in the refrigerator group, by 4% in the tumble dryer group and by 9.6% in air conditionergroup according to previous year.

This TCFD report refers to the financial year 2021 and considers the TCFD recommendations published in 2017. It contains references to our CDP Climate Change Report 2022 available at our corporate website. In the coming years, we plan to further develop this index and integrate the recommendations in our annual integrated reporting.

| Topic |

Recommended disclosures |

Section & comments |

Page references

(CDP Climate Change Report 2021)

|

| Governance |

| Disclose the organization’s governance around climate-related risks and opportunities |

a) Describe the board’s oversight of climate-related risks and opportunities. |

CDP C1.1b CDP C.1.1d |

p.4-5 |

| b) board member with competence on climate-related issues |

CDP C.1.1d |

p.5 |

| c) Describe management’s role in assessing and managing climate-related risks and opportunities |

CDP C1.1b CDP C1.2, C1.2a |

p.4-6 |

| d) incentives for the management of climate-related issues |

CDP 1.3, C1.3a |

p.8-9 |

| Strategy |

| Disclose the actual and potential impacts of climate-related risks and opportunities on the organization’s businesses, strategy, and financial planning where such information is material. |

a) Describe the climate-related risks and opportunities the organization has identified over the short, medium, and long term. |

CDP C2.1a, C2.1b CDP C2.3, C2.3a CDP C2.4, C2.4a |

p.9-10 and p.13-20 |

| b) Describe the impact of climate-related risks and opportunities on the organization’s businesses, strategy, and financial planning. |

CDP C2.3a

CDP C2.4, C2.4a

CDP C3.3

CDP C3.4, C3.4a

|

p.13-20 and

p.23-24

|

| c) Describe the resilience of the organization’s strategy, taking into consideration different climate-related scenarios, including a 2°C or lower scenario. |

CDP C3.1, C3.2, C3.2a, C3.2b

|

p.20-23

|

| Risk Management |

| Disclose how the organization identifies, assesses, and manages climate-related risks. |

a) Describe the organization’s processes for identifying and assessing climate-related risks. |

CDP C2.1, C2.1b

CDP C2.2, C2.2a

|

p.9-13 |

| b) Describe the organization’s processes for managing climate-related risks. |

CDP C2.1b

CDP C2.2

CDP C2.3a

CDP C2.4a

|

p.10-11

p.13-20

|

| c) Describe how processes for identifying, assessing, and managing climate-related risks are integrated into the organization’s overall risk management. |

CDP C2.2

|

p.10-11

|

| Metrics and Targets |

| Disclose the metrics and targets used to assess and manage relevant climate-related risks and opportunities where such information is material |

a) Disclose the metrics used by the organization to assess climate-related risks and opportunities in line with its strategy and risk management process. |

CDP C1.3, C1.3a

CDP C4.2,

|

p.8-9 and

p.27

|

| b) Disclose Scope 1, Scope 2, and, if appropriate, Scope 3 GHG emissions, and the related risks. |

CDP 5.2

CDP C6.1

CDP C6.3

CDP C6.5

CDP C7.1, C7.1a, C7.2, C7.3,C7.3c, C7.5, C7.6, C7.6b, C7.9, C7.9a, C7.9b

|

p.33-52

|

| c) Describe the targets used by the organization to manage climate-related risks and opportunities and performance against targets. |

CDP C4.1, C4.1a

CDP C4.2, C4.2c

CDP C8.1, C8.2, C8.2a, C8.2b, C8.2c, C8.2g

CDP C12.1, C12.1a, C12.1b, C12.2, C12.2a, C12.3, C12.3b, C12.4

|

p.25-28

p. 52-56

p.61-66

|

Vestel Elektronik – 2020 Energy Efficiency and Carbon Footprint Improvement Activities

| Project Description |

Annual CO2 Savings (tonnes) |

| Reducing Chrome Plating Times |

4.48 |

| Replacing Paint Shop Production Area Lighting with LEDs |

5.86 |

| Replacing Machine Lighting with LEDs |

0.29 |

| Preventing Steam Leaks in the Molding Room |

4.36 |

| Using Shared Compressors in Plastic Injection and High-End Factories |

57.19 |

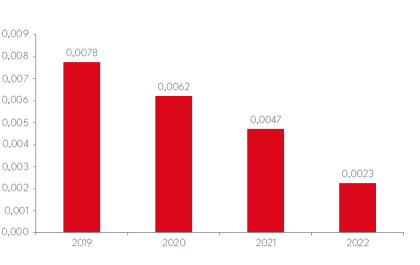

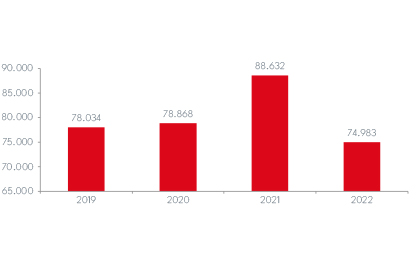

Vestel Elektronik Sanayi ve Ticaret AŞ – Total Carbon Emissions (tonnes CO2/year)*

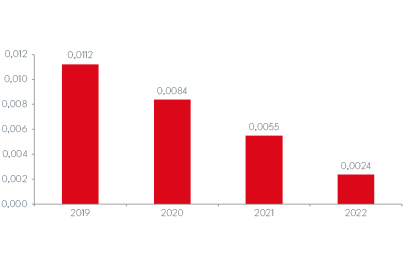

Vestel Elektronik Sanayi ve Ticaret AŞ – Total Carbon Emissions (kgCO2/TL revenues)*

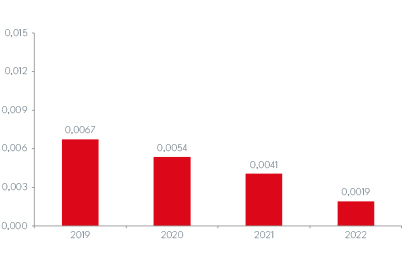

Vestel Elektronik Sanayi ve Ticaret AŞ – Carbon Emissions Originating from Energy Consumption (kgCO2/TL revenues)*

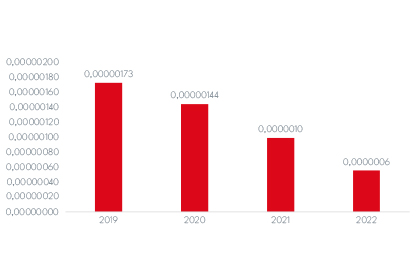

Vestel Elektronik Sanayi ve Ticaret AŞ - Carbon

Disclosure Project Reports

Vestel Elektronik San ve Tic AŞ – TCFD Report

Vestel Beyaz Eşya – 2020 Energy Efficiency and Carbon Footprint Improvement Activities

| Project Description |

Annual CO2 Savings (tonnes) |

| Bypassing the Air Line Between Utilities 1 and Utilities 3 |

1,199 |

| Bypassing the Chiller Cold Water Supply Between Utilities 1 and Utilities 3 |

3,531 |

| Washing Machine-2 Factory – Reducing the Air Pressure Need of the Cabin in the Drying Paint Shop from 6 Bars to 5.2 Bars |

70 |

| Extruder-1 Reducing Maintenance Costs and Saving Energy by Replacing the Main Engine |

372 |

| Refrigerator-2 Factory – Saving Energy by Using an Infrared System in the Paint Shop Drying Oven |

142 |

| Refrigerator-2 Factory – Saving Energy of Machine Cooling Water |

254 |

| Refrigerator-2 Factory – Reducing Malfunctions and Spare Part Usage by Installing a Central Vacuum System |

252 |

| Saving Energy in Chiller Machines at Utilities |

168 |

| Refrigerator-2 Factory – Saving Energy in Paint Shop Air Handling Unit |

166 |

| Extruder-2 Reducing Maintenance Costs and Saving Energy by Replacing the Main Engine |

159 |

| Gate-2 Saving Energy by Removing Hydraulic Pistons |

140 |

| Saving Energy by Switching From Asynchronous Motors to IE3 Efficient Motors in All Refrigerator Factories |

125 |

| Refrigerator Factories - Saving Energy with the Daylight Project in Lighting |

40 |

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Total Carbon Emissions(tonnes CO2/year)

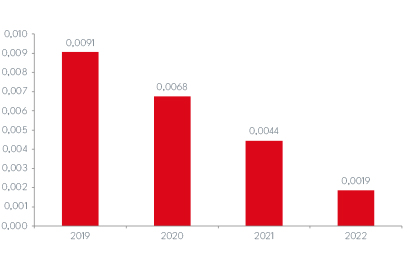

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Total Carbon Emissions(kg CO2/TL revenues)

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Carbon Emissions Originating from Energy Consumption(kg CO2/TL revenues)

Vestel Beyaz Eşya San ve Tic AŞ – TCFD Report