Vestel Group of Companies (“Vestel”), which consist of Vestel Elektronik Sanayi ve Ticaret AŞ (“Vestel Elektronik”) and Vestel Beyaz Eşya Sanayi ve Ticaret AŞ (“Vestel Beyaz Eşya”); has committed the following items in its Management Systems Policy regarding to the energy owned within the scope of ISO 50001 Energy Management System Certificates.

- We will use efficient, environmentally friendly technologies, equipment and services to continuously improve our energy performance and increase the rational and efficient use of energy ,

- We will increase the use of renewable energy sources.

- When designing new projects, we will apply the best available technologies and give priority to the design of products with energy efficiency and high energy performance.

- In order to achieve energy consumption reduction objectives, we will raise awareness about energy efficiency by ensuring the participation of all stakeholders with an effective internal and external communication strategy, and we will support the use of new technology and creative ideas.

- By benchmarking our energy performance with the best one and similar ones in the world, we will identify areas for improvement in energy efficiency and carry out energy audits regularly in order to achieve energy objectives.

- We will purchase energy-saving, efficient, new technology products and services.

ENERGY EFFICIENCY AT PRODUCTION

At Vestel, energy performance results are regularly monitored and evaluated by senior management.

In order to effectively manage the Energy Management System at Vestel, Energy Managers are available as per the legislation. Creating the processes and systems necessary to increase energy efficiency, Vestel carries out the implementation and sustainability of these processes and systems in an integrated manner with the ISO 50001 Energy Management System Standard it has in all energy types.

Within the scope of TPM (Total Productive Maintenance) practices carried out, there is an "Energy Committee" in all white goods factories to raise awareness about energy, to expand Kaizen studies and to improve energy performance.

In 2022, the company launched a total of 15 main energy efficiency projects, saving 7,200 MWh of energy and TL 18 million. This corresponds to the electricity consumption of 1,940 people in Turkey. In its electronics plants, it reduced total natural gas consumption per unit product by 4%. On the other hand, in its household appliances plants, it reduced total natural gas consumption per unit product by 3.7% and total hot water consumption per unit product by 27% compared to the last year. Thanks to these projects, Vestel prevented 3,290 tonnes of carbon emissions.

The Company can instantaneously monitor the consumption of all energy points online at the Data Monitoring and Control Center of Vestel Beyaz Eşya, and it keep energy consumption under control in light of the data obtained. Thanks to the Data Monitoring and Control Center, it achieved energy savings of TL 6.2 million in 2022.

ENERGY EFFICIENCY AT PRODUCTS

Vestel offer LED lighting products with high energy efficiency in industrial, road/street/garden, sports and area lighting categories. These products save up to 40% energy, do not harm the environment and human health with their mercury-free

composition, and reduce waste generation as they can be used for more than 200 thousand hours.

With new products such as UHD, OLED, Mini LED and 8K that have been added to the television product line and continue to be added, the power consumption of TVs is increasing every year. Vestel with its power saving efforts in recent years, It has achieved the high energy class in most of the TV products.

The transition period of labelling application began in November 2020 and has become mandatory from March 2021. According to this new labelling application Vestel updated the energy class table and started to use new energy labels.

Vestel designs products with the highest energy efficiency class in the market. In this context, The Company offers its consumers efficient and user-friendly refrigerators, washing machines, tumble dryers, dishwashers, cooking appliances and air-conditioners thanks to the technologies it has developed. Vestel designs tumble dryers with weight sensors. Thus, the most efficient drying mode is selected by determining the amount of load in the machine and energy saving is achieved. It produces ovens with HeatWrap technology that can cook five trays at the same time, and induction hobs with much higher thermal efficiency than gas stoves.

LABOR PRACTICES AND HUMAN / EMPLOYEE RIGHTS

Vestel respect, protect and observe the human rights of our employees. The Company strives to provide a decent, respectable, egalitarian and fair working environment enshrining human dignity. In this regard, it is committed to full compliance with the Universal Declaration of Human Rights, the laws and standards set by the International Labor Organization (ILO), and the legal framework and legislation regulating human rights and work life in Turkey. In addition to this, Vestel continues to work on compliance with human rights as a signatory to the United Nations Global Compact (UNGC). It does not tolerate discrimination in any of our human resources processes, starting with recruitment practices. Vestel does not discriminate people based on gender, age, religion, language, race, sect, social status, physical build, ethnicity, nationality, sexual orientation or any other personal feature. It offers its employees equal opportunities in line with their skills and experience. The Company also applies an equal pay policy for equal work in its remuneration system. Vestel do not tolerate child labor, forced labor and human trafficking. It is also working on developing a due diligence process to control compliance with human rights in the value chain. Compliance with human rights in our own production facilities is audited annually under the Social Compliance Audits (BSCI, SEDEX, etc.) performed by its customers.

Vestel continue to create and develop the most ideal working environment for the health, safety, rights and personal

development of its employees. Vestel develops human resources policies that facilitate the adaptation processes of employees, encourage their professional success and development, respond to their expectations and needs by considering fairness and equal opportunities, and contribute to national employment.

Vestel aims to evaluate and improve the opportunities it provide to its employees as well as the working environment through the Employee Satisfaction and Engagement Survey that it organizes every two years. The Company shares the results of the survey with the senior management, breaking it down based on the age group and gender categories. In the last two years, Vestel’s employee satisfaction score has increased by 8% and its employee engagement score by 9%.

Common fringe benefits for all of its employees include transportation, meals, childcare support, education scholarships

offered by Zorlu Holding’s Mehmet Zorlu Foundation for the successful children of employees, marriage, maternity and

bereavement leaves, cash aid, four shopping cheques per year, the right to use the fitness center in Vestel City, discounts on Vestel-branded products and additional bonus payments to those who have completed their Master’s and PhD studies.

Vestel designs its training activities with the aim of discovering and developing employees who are capable of thinking,

researching, questioning and who are creative, entrepreneurial and productive. In today’s world, where the need for competent human resources is constantly increasing, it plans and implements its training investments for employees in terms of sections, departments and projects. Vestel does not only invest in its own employees, but also in the development of dealer and authorized service provider employees. The Company analyzes the trainings received by employees by breaking down the data by age group, gender, management level and type of training.

Through the sustainability goal of “Corporate Well-Being” at the Vestel Group of Companies, it developed the “Viva!” Project to improve the quality of life of employees and to ensure that they lead a long-term corporate life. Vestel started to implement this project by integrating it with Zorlu Holding’s “We Are Good Together” Project and the Wellbees application in 2020.

The We Are Good Together Project Covers:

- Activities aimed at protecting physical and mental integrity,

- Seminars and workshops on good and healthy lifestyles,

- A common sharing platform with event announcements,

- E-mail content and notifications to boost employee motivation,

- Adopting the motto “Working at Vestel means better living” and activities organized for this purpose,

- Awareness-raising information sharing for healthy living,

- Spreading the corporate culture and creating sharing environments that strengthen the communication between the Human Resources Department and employees,

- Suggestions and practices for improving Vestel’s physical conditions.

One of Vestel’s important goals under its sustainability approach is to increase corporate volunteering efforts. Under the “Kıvılcımlar (Sparks) Movement”, launched in 2019, it organizes volunteer activities under five main groups within the Vestel Group of Companies: “environment”, “children”, “persons with disabilities”, “reuse of materials” and “our friends: animals”.

According to the renewed targets within the scope of Zorlu Holding Smart Life 2030, Vestel:

Vestel Beyaz Eşya holds world records in energy saving with its:

- Investing in the future of work, being a leader in inclusion and diversity,

- To be the most preferred company by employees in all sectors,

- Being a pioneer in social investments and allocating 1% of EBITDA every year to Sustainable Development Goals will contribute to the umbrella goals.

- To reach 40% female employee rate in the total workforce.

- To increase the average annual training hours per employee over 20 hours.

For more detailed information on our workforce practices and our approach to human and employee rights, the Vestel Elektronik and Vestel Beyaz Eşya Annual Reports and the Global Compact can be viewed.

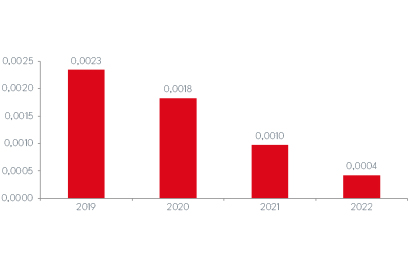

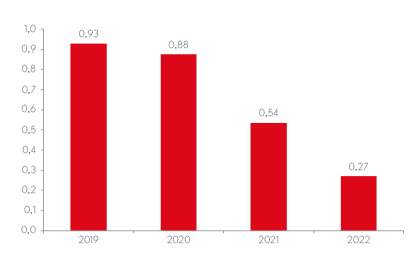

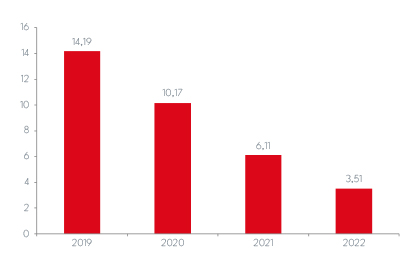

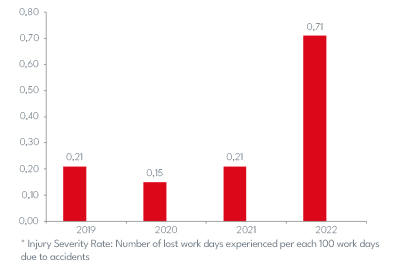

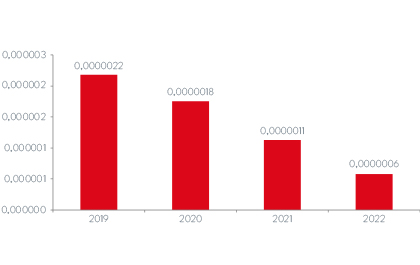

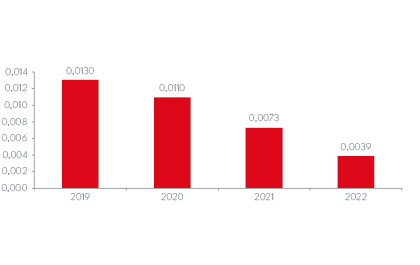

Vestel Elektronik Sanayi ve Ticaret AŞ – Total Energy Consumption (TEP/TL revenues)*

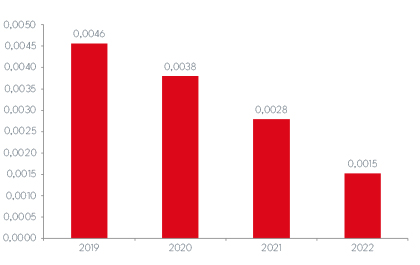

Vestel Elektronik Sanayi ve Ticaret AŞ – Electricity Consumption (kWh/TL revenues)*

Vestel Elektronik Sanayi ve Ticaret AŞ – Natural Gas Consumption (kWh/TL revenues)*

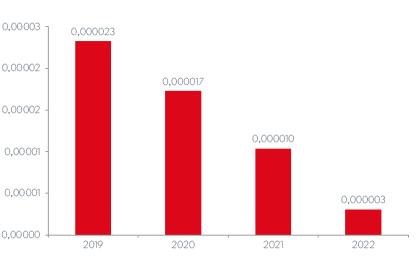

Vestel Elektronik Sanayi ve Ticaret AŞ – Diesel Consumption (litre/TL revenues)*

Vestel Elektronik Sanayi ve Ticaret AŞ – Steam Consumption (kWh/TL revenues)*

Vestel Elektronik Sanayi ve Ticaret AŞ – Thermal Energy Consumption (kWh/TL revenues)*

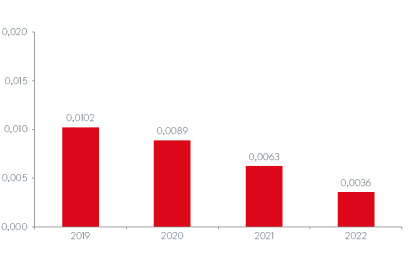

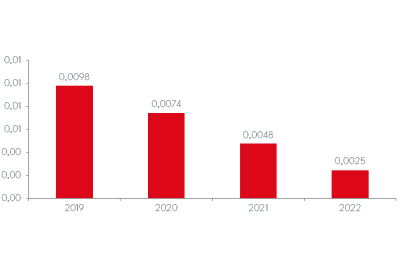

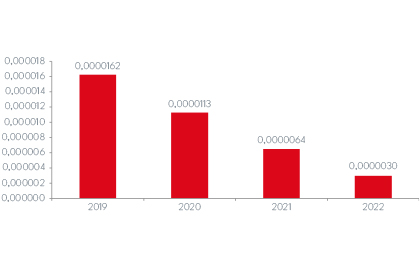

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Total Energy Consumption (TEP/TL revenues)

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Electricity Consumption (kWh/TL revenues)

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Natural Gas Consumption (kWh/TL revenues)

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Diesel Consumption (litre/TL revenues)

Vestel Beyaz Eşya Sanayi ve Ticaret AŞ – Hot Water Consumption (kWh/TL revenues)